OSP Biocide Selection Guide

PROTECT YOUR INVESTMENT AND

OPTIMIZE OPERATIONS BY CHOOSING

THE RIGHT BIOCIDE AT THE RIGHT TIME

SUPPORT PROGRAM SUCCESS & CONTINUITY OF OPERATIONS

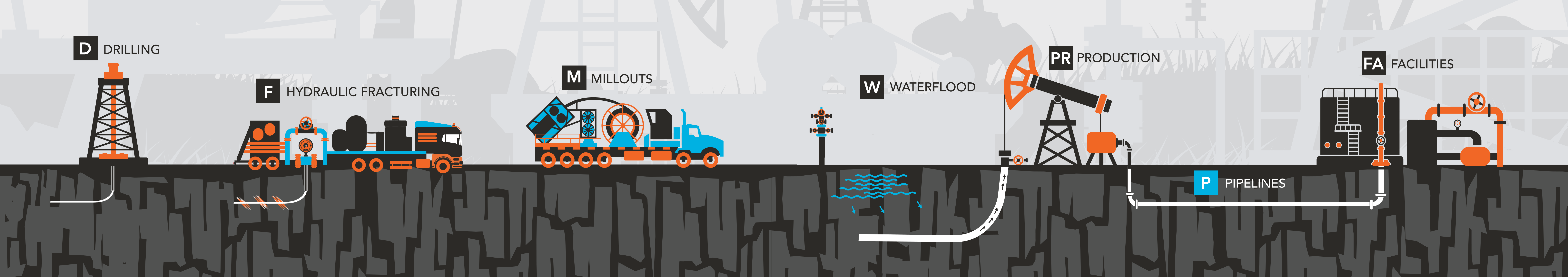

Where there is water, there are microbes — from drilling mud, stimulation fluids, produced water, proppant, finished fuels, in the reservoir and in pipelines — and if left untreated, they can cause fouling, souring, corrosion and create costly setbacks.

For 30 years, OSP has built a reputation as the go-to microbial expert specializing in microbial identification, surveillance and mitigation.

We support clients in understanding their microbial environment so they can protect their assets and prevent future challenges.

Effective operations, asset longevity and equipment integrity rely on proper chemical control programs that use biocides — chemical substances applied in oil and gas systems — to kill, inhibit or control microbial communities.

If improperly monitored or managed, microbes can lead to severe corrosion, souring, product degradation, biofouling — and costly disruptions. Some biocide applications are preventative in nature, while others are meant to manage a microbial activity long term.

Choosing the right biocide at the right time for your unique application is key in ensuring program success and smooth operations.

My Primary Objective Is:

Prevent reservoir contamination

Prevent water storage souring and odor issues

Delay the onset of H2S production from newly completed well

Maintain completion fluid stability

Protect my completion assets

Prevent microbial corrosion in pipelines and production asset

Design a Custom Solution

Problem Solve

- Conduct a biocide program review.

- Run a DNA profile of producing wells.

- Evaluate previous source waters.

- Review on-site treating logistics.

Design

- Choose preferred biocide options & review suitability.

- Run DNA profile and ATP testing on preferred source waters.

- Conduct a kill study to determine appropriate biocide and dosages.

- Source biocides for program requirements.

Apply

- Test onsite to confirm parameters are within range.

- Monitoring application to confirm dosage KPI are met.

- Test flowback and into production life to validate application success.

OSP IS HERE TO HELP!

CLIENT SUPPORT & COLLABORATION

We know our niche, we are very passionate about our work and we are very good at what we do. We sell data-driven applications, not just biocides. Not only will we provide you with competitive pricing to any of the registered oilfield biocides, but we back up what we sell to our partners with the information needed to drive the right decisions to support our recommendations on chemistry and dosages. What else sets OSP apart?

- We are responsive an available as needed for product support, application support, troubleshooting, or testing.

- We have direct knowledge of basins, frac program logistics, industry biocide tool kit, and available testing technologies.

- We are flexible and understand client preferences, logistics limitations and the variable nature of our industry.

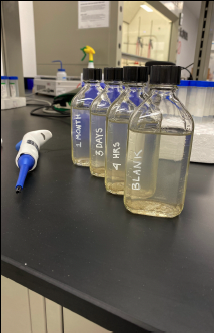

MICROBIAL TESTING OPTIONS

OSP offers a number of services under our LifeCheck brand for

microbial testing, including:

- ATP Testing

- DNA qPCR

- RNA qPCR

- DNA 16S Sequencing

- Kill Studies, Biocide Selection Studies, Dosage Optimization

- Studies

- Program Reviews

- Program Recommendations

ROBUST BIOCIDE PRODUCT LINE

OSP offers a complete line of registered biocides for the oilfieldOur suite includes winterized options, as well as a number of solid chemistries (water soluble packs, jugs of granular, bugsticks). These options are optimized to treat frac tanks, saddle tanks, treater trucks and a number of production applications.

In addition, OSP has access to the majority of the registered oilfield biocides and has a strong network of partner blending facilities in all of the major basins, which allow us to provide very competitive pricing. We are continuously adding to our biocide product line to ensure we have the right solutions for our clients applications. Give us a call to find the right product for your application or initiate a selection study!

SELECT YOUR BIOCIDE

Liquid

- 2K7 SLN– 10% bronopol

- DB7 SLN– 20% DBNPA

- DB7 SLN– 5% DBNPA

- MB7 – 99% MBO

- GQ2510 – 25% glut 10% quat

- GQ2512 – 25% glut 12% quat

- GQ123 – 12% glut 3% quat

- GQ510 – 5% glut 10% quat

- GQ52 – 5% glut 2% quat

- QD10 -10% DDAC

- QD50 – 50% DDAC

- 2K7Q1 – 5% bronopol 1% DDAC

- Glut – 50% active

- Glut – 25% active

- Glut – 15% active

- DMO – 78% DMO

- Dazomet – 24% active

- PAA – 15% active

- THPS – 20% active

- THPS – 75% active

- THPC – 80% active

- TTPC – multiple % active

- ADBAC – multiple % active

- Isothiazilinone – (CMIT/CMI/MI/BIT)

- THMN

Solid

- DB7 EPack – 96% active DBNPA

- (solid, water-soluble packs)

- DB7 Granular – 96% active DBNPA

- (solid, 3lb jugs, 44lb pails)

- 2K7 WSP – 99% active bronopol

- (solid, water-soluble packs)

- 2K7 Granular – 99% active

- bronopol (solid, 3lb jugs, 55lb pail)

- 2K7 Bugsticks – 86% active

- bronopol (solid stick 118g)

- 2K7 Slimstick – 86% active

- bronopol (solid stick 39g)

- CTAC

Winterize

- GQ2512W – winterized 25% glut

- 12% quat – Freeze Point: -40 °C/°F

- GQ123W – winterized 12% glut 3%

- quat – Freeze Point: -40 °C/°F

- GQ510W – winterized 5% glut 10%

- quat – Freeze Point: -40°C/°F

- QD10W – winterized 10% DDAC –

- Freeze Point: -40 °C/°F

- DB7W – 20% DBNPA- Freeze

- Point: -34°C/-29°F

- 2K7-WM (bronopol) – Freeze Point:

- -40 °C/°F